BNC is the only cellulose that can be produced in the form of a nanofibre network from low-molecular substances such as glucose by acetic acid bacteria.

The development of BNC products with customised properties is one of our core competencies.

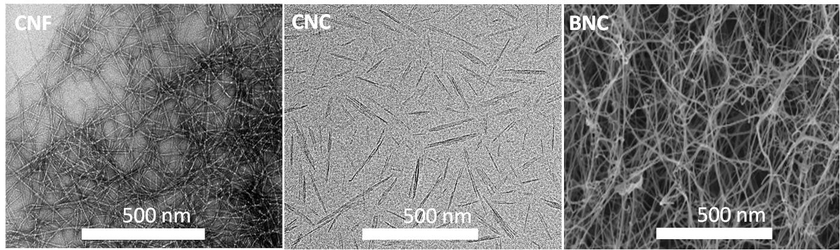

Nanocelluloses combine the outstanding properties of the natural material cellulose with the specific characteristics of nanomaterials and are characterised by at least one dimension in the nanometre range.

The family of nanocelluloses can be divided into three areas that differ significantly in terms of starting material, manufacturing process and product properties. These types are: Cellulose Nanofibres (CNF), Cellulose Nanocrystals (CNC) and Bacterial Nanocellulose (BNC).

Biotechnologically produced natural cellulose hydrogels, unlike conventionally produced cellulose, are variable in structure, purity and property.

Bacterial nanocellulose (BNC)

- natural polymer with high application potential for medicine and technology

- Synonyms: Biotech cellulose, microbial cellulose, biocellulose.

- Biotech synthesis from glucose

- in aqueous culture medium and in the presence of air, acetic acid bacteria form BNC

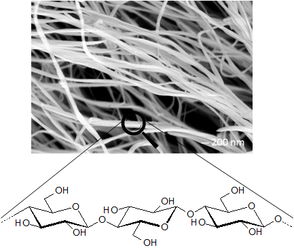

- Molecular formula identical to plant cellulose: (1→4)-β-D-glucopyranan, but without accompanying components such as hemicelluloses and lignin

- 100% purity

- > 80% crystallinity

- Thermostability up to 250 °C

- High mechanical strength (up to 30 GPa)

- Formation of a microporous nanofibre network (1% cellulose and 99% water)

Mobile Matrix Reservoir Technology (MMR-Tech)

* Apparatus for the production of hollow bodies made of microbial polymer (DE10 2012 201 272 B4)

Process for the production of hollow bodies from microbial cellulose (DE10 2012 201 268 A1)

Medical implant based on nanocellulose (EP 3331 583 A1, CN 1082 89978 A, US 02018 0221 129)

Our patented MMR-Tech* is a dynamic synthesis method and enables process-controlled design of function-defining properties of BNC products to meet individual requirements.

- Direct formation of hydrogel moulded bodies (tubes, surfaces, 3D bodies) on templates

- Template material is variable (e.g. wood, polymers, textiles, non-toxic metals)

- Surface design

- BNC formation is layer-by-layer, so that defined multi-layer systems can be built up for the first time

- Design of the nanofibre network

- Targeted drying (influencing the pore system)

- Addition of additives (composites)

- Coating

Further literature:

Klemm, D.; Petzold-Welcke, K.; Kramer, F.; Richter, T.; Raddatz, V.; Fried, W.; Nietzsche, S.; Bellmann, T.; Fischer, D. BiotechKlemm, D.; Petzold-Welcke, K.; Kramer, F.; Richter, T.; Raddatz, V.; Fried, W.; Nietzsche, S.; Bellmann, T.; Fischer, D. Biotechnanocellulose: A review on progress in product design and today’s state of technical and medical applications. Carbohydr. Polym.2021, 254, 117313.

We are also happy to develop customised products for you!